One application that we have been able to use our solenoid valves in has been dentist chairs.

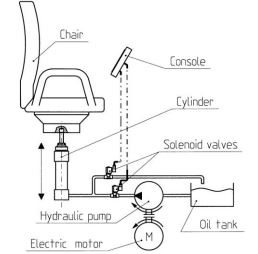

The function of the solenoid valves is used in the hydraulic action of lifting the chair.

Solenoid valves used in dentist chairs

Integrated station with all the necessary dental or ophthalmic equipment, complete with automatic chair and adjustable lamp. All automatic functions are easily run by the operator through a console. The chair lifting system works under the thrust of a hydraulic cylinder operated by the medium (oil). Compared to a mechanical system, the hydraulic thrust has the advantage of a “smoother” movement.

Two solenoid valves are used in this application to regulate the height of the chair. Oil is taken from the basin by the pump and let into the circuit at a pressure of 12-13 bar. When a button is pressed on the console, the solenoid valve is operated: it intercepts oil in the pump and sends it to the cylinder. The cylinder enables hydraulic energy to be turned into mechanical energy thus lifting the chair to the desired height. By pushing another button, the second valve opens. Under the effect of the overhanging weight, oil under pressure inside the cylinder is exhausted into the basin, and the chair is pushed down.

The type of solenoid valve that would be used in this application would be:

A special version of valve D263 is recommended for this application. Unlike the standard valve, it is equipped with a cone-shaped spring on the plunger, with a heavier load. With this option, fixed core and plunger do not stick due to the viscosity of the medium when the valve closes (i.e. when the coil is de-energized). The plunger is equipped with a Ruby seal to guarantee very high performances.