Standard Solenoid Valve Types

Direct Acting Solenoid Valve

Direct acting solenoid valves are available in both normally closed (NC) and normally open (NO) variants and with either two connections and one flow passage (2/2 way) or three connections and two flow passages (3/2 way).

You can find the full M&M International UK range of solenoid valves here

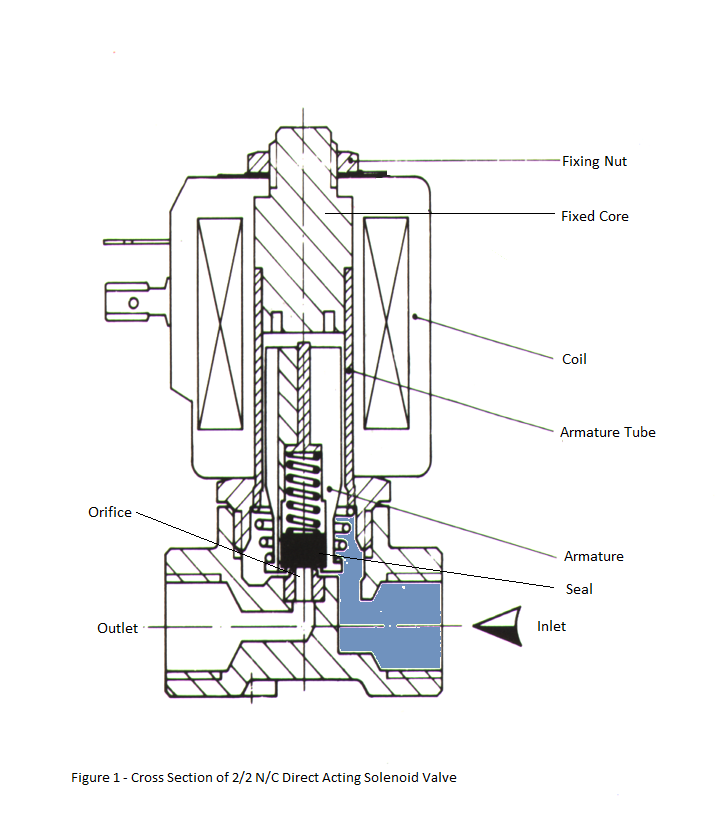

Figure 1 below shows a 2/2 way NC Direct Acting Solenoid Valve. In this example, when the coil is de-energised, the armature is held down on to the valve orifice by the spring surrounding the armature. The seal is located at the bottom of the armature and prevents the flow of the media through the valve orifice. When the coil is energised the electro-magnetic force created is enough to overcome the force of the spring and the armature is attracted up towards the fixed core. This moves the seal away from the orifice allowing the media to flow from the inlet, through the orifice and valve body, to the outlet connection. The valve remains open until the coil is de-energised.

With the normally open version of this valve – 2/2 NO Direct Acting – the spring is located on the bottom of the armature and, when the coil is de-energised, holds the armature and seal off the orifice allowing the media to flow through the body. When the coil is energised the armature and seal are forced down onto the orifice sealing the valve and stopping the flow.

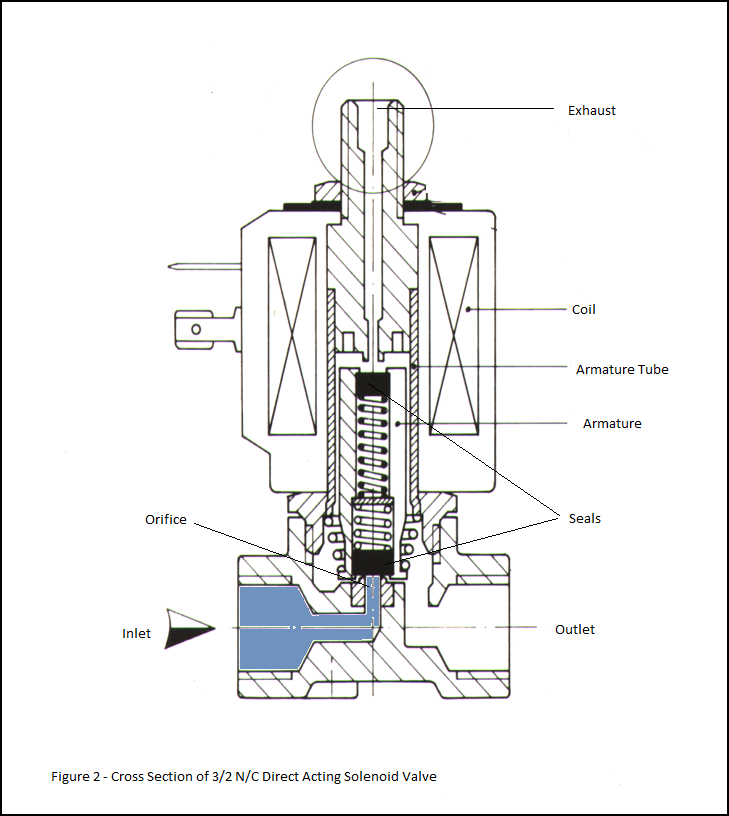

Figure 2 shows the operation of a 3/2 way NC version of a Direct Acting Solenoid Valve. The armature has two seals - one on the top and one on the bottom of the armature. The armature tube has an opening at the top creating an exhaust port. When the coil is de-energised the main orifice is sealed by the armature and seal preventing flow through the valve. As with the 2/2 way version, when the coil is energised, the lower seal is lifted away from the orifice to allow the media to flow to the outlet connection.

At the same time the upper seal prevents flow to the exhaust port. When the coil is de-energised the lower seal closes the main orifice and downstream pressure is exhausted through the top of the valve. The exhaust port can also be used as an inlet so that when the coil is de-energised the valve acts as normally open with flow travelling from the exhaust port to the outlet.

The 3/2 NC Direct Acting Valve allows media flow from inlet to outlet when the coil is de-energised and pressure exhaust through the tube when energised.

Unlike pilot operated valves, direct acting solenoid valves do not use a diaphragm and so do not require a minimum pressure or pressure differential to operate. The valve will operate at zero pressure up to the rated maximum. The maximum pressure and flow rates depend directly on the orifice size and the coil power. They have an average response time of 5 – 25ms.

Some direct acting solenoid valves are available with a manual override switch that allows the valve to be operated independently of electrical current.

Purchase Solenoid Valves online through the V-Flow Solutions web shop